Understanding the Durability of Wood

In the first of two articles, PCA member Gervais Sawyer considers why wood is durable or, to put it another way, why is it NOT durable? In a second article he will consider how it can be made more durable.

Rather than presenting you with bald scientific facts, let us compare the growth of a tree with your own business so that you will see how the laws of evolution govern why things are as they are.

Trees are wood/timber machines

Consider a tree and your business as a machine. The tree is essentially a machine for fixing solar energy. To do that it functions as a pump that has a plumbing system to get water (and lots of it) up to the factories, the leaves, where carbon dioxide and water are combined into sugars, thus fixing the energy of the sunlight. The process is not very efficient, perhaps just 2% of the solar radiation is fixed, much of it being reflected back into space, and of course all the other living cells in the tree are busy releasing carbon dioxide. The sugars synthesized then have to be transported down the tree to supply all the living cells that make the tree work, like growth, roots, new leaves etc. This done by the inner bark and by horizontal cells that move food inwards (rays).

Evolution has resulted in different trees developing different strategies for spending that 2% of fixed energy in sunlight. For example, the tree might spend a lot of energy on growth for height so as to compete for light, like the fast growing poplars. Another species might grow more slowly but invest energy in synthesizing protective chemicals to ward off diseases and browsing animals and insects, such as oak. Yet another species might invest its energy in reproduction, producing lots of fruit and nuts. When forests are managed for fastest growth by regular pruning and thinning, the tree is tricked into thinking that next year will be one when the business will grow and expand, so it keeps plenty of spare cash (food stores) readily available. This area of the tree is known as the sapwood and is often of much lighter colour, and for a fast growing tree can be a very wide band. In the pine trees used for telegraph poles, this band can be 75mm (3”) or more. As you will know very well in your business, it is not a good idea to have lots of cash lying around because it is just waiting for some opportunist person to come and grab a share. In the case of the tree, that would be insects and fungi. This occasionally happens to living trees, but in general the bark forms a nice protective jacket that keeps keeps organisms out and the water in, thus limiting the available oxygen necessary for decay. In any event, if the bark is damaged, the tree has healing mechanisms to isolate the area. For example, damage a pine tree or drill a hole in the bark and the tree will respond by flooding the area with sticky resin.

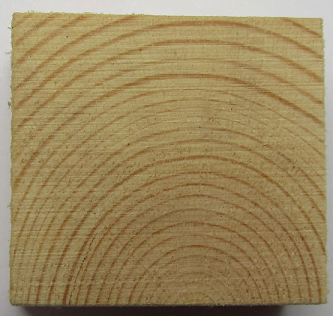

It can therefore be said that the sapwood of ALL trees is readily decayed if conditions permit. The worst case situation against which things are measured is to plant a stake of timber in the ground. This stake must be made of heartwood. There is no point in testing sapwood because it is always easily decayed. The heartwood may or may not contain various extractives that are toxic to insects and fungi. The soil provides not only plenty of moisture and nutrients but also plenty of bacteria and fungi waiting to have a go. But how can you tell if it is sapwood? In some timbers there is an easily visible colour contrast (pine, oak, mahogany) Figure 1. but in many there are no clues (spruce, fir, beech, birch) Figure 2.. If you look at the end grain for the growth rings you can often judge how near the centre of the tree the wood is. If on the other hand the growth rings are very flat or there is a little bit of bark you know that you are on the outside and therefore probably sapwood.

In this piece of pine, there is a contrast between heartwood and sapwood. The curvature of the growth rings gives you an idea of how near the centre or bark you are.

But in this piece of spruce, there is no difference in colour. However, the outside of the log is visible at the top left hand corner, so some of this is sapwood.

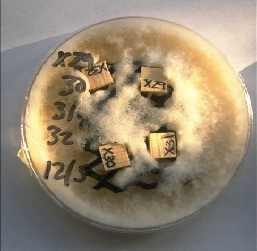

So, how can we classify durability? Firstly we need data from lab and field tests and add in records of service life and anecdotal evidence. For the lab tests we expose small blocks of pine sapwood to cultures of fungus and observe the weight loss. Figure 3. Field tests use graveyard tests on heartwood stakes. Figure 4.

These heartwood stakes that have been planted in the ground will be inspected regularly until they fail when gently tapped with a hammer. A classification can be assigned according to how many years have elapsed. It makes the big assumption that all graveyard test sites are the same and is one reason why the classification should be used with caution.

Figure 3. Laboratory test for durability

Figure 4. A graveyard test site

Secondly, there is a classification system. Unfortunately there are several ways of classifying durability around the world, but in Europe it is spelt out in EN350-1. The classes are in descending order:

Class 5 Not durable < 1 year Sapwood of ALL timbers. Birch, poplar, beech

Class 4 Slightly durable Scots pine, spruce

Class 3 Moderately durable Douglas Fir, Larch

Class 2 Durable Oak, chestnut, utile, Canadian western red cedar

Class 1 Very durable. Teak, greenheart, jarrah

Remember that this is for ground contact, but there are other situations in which wood is used, so it is necessary to consider the hazard class to which they will be exposed.

In considering the hazard class a number of factors must be taken into account. What is the natural durability of the wood, what are the special biological hazards, what is the climate, how does the design contribute, and how much maintenance is likely?

This translates into Use Classes, which are:

Class 1. Internal, dry, above ground components where wetting is highly unlikely.

Class 2. Internal, above ground where there is a risk of wetting.

Class 3. External above ground. Windows, cladding etc.

Class 4. Ground contact. Fence posts, poles, sleepers, fresh water

Class 5. Salt water. Risk of marine borers.

So much for the natural properties of wood. In the next article I shall consider how wood can be protected. How far can good design protect wood, what has been done historically and what can we do now? It is a story full of good news and bad, that should convince you that it is worth knowing what can be achieved and more importantly how to check that it has been achieved.

We delivering a course – Wood Identification for the Infestation Wood Surveyor. Click here for further information.